China Rare Earth Magnet Limited is a professional manufacturer of alnico rod magnets.

Rod is one of the most commonly used shapes of alnico magnets..

If alnico permanent magnets are needed for your products, please send us an enquiry with the information as follows:

Material: Cast Alnico Magnets / Sintered Alnico Magnets

Size & shape: U-shape, horseshoe, block, disc, ring, arc or other complex shapes etc.

Tolerance: For normal dimensions, the tolerance is about +0.05/-0.05mm. If customers have special requirements on it, please communicate with us.

Grade: Alnico 2 – Alnico 9, FLN8-FLNGT42, LN9-LNGT72--- (Magnetic Property Sheet)

Surface Finish: Alnico magnet itself is superior in corrosion resistance, no coating or other surface treatment is needed normally.

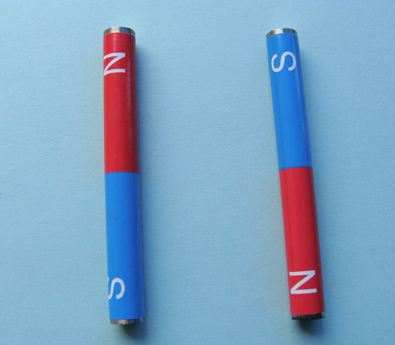

If necessary, they can be coated in nickel, or sprayed in red, blue, green, or environmental protection paint in other colors.

Magnetized or not: To be supplied in Magnetized or Un-magnetized condition

Magnetization Direction: e.g. through height (Sketch Map)

Quantity (pieces):

Alnico permanent magnet is a hard alloy of aluminum, nickel, cobalt, iron and some other trace metal elements.

Casting and sintering are two different manufacturing processes of Alnico magnets. They are called cast Alnico magnet and Sintered Alnico magnets.

By casting technology, alnico magnets can be customized into different sizes and shapes.

Comparing with casting Alnico magnet, the size of sintered Alnico magnet is relatively small, but its dimensional tolerance is better than that of cast one.

Besides, the magnetic performance of sintered Alnico is somewhat lower than Casting Alnico one.

The most significant feature of Alnico magnets is they can work properly under a very high temperature above 500°C.

Alnico magnets are mainly used for various fields like sensors, instruments, electronics, mechanical and electrical, medical, teaching, automotive, aviation, military technology and other applications.