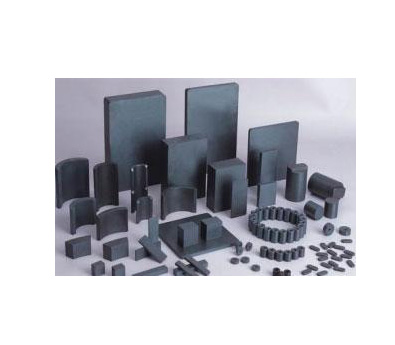

Ferrite Magnets

Introduction Features Neodymium Magnets VS Ferrite Magnets Updated Posts on Ferrite Magnets or Assembly: What are the advantages of black ferrite magnets China?

Ferrite magnets are permanent magnets , not rare earth magnets, it is mainly made from iron oxide and strontium carbonate by ceramic processing technology, also called ceramic magnets.

Ferrite magnets are brittle, can be manufactured by die pressing and then sintering, can be made into various shapes and sizes. Its normal operating temperature is between -40℃ and 250℃. Ceramic magnets are the most commonly used permanent magnet materials due to their low cost, easy to produce, excellent corrosion and demagnetization resistance properties. It can be produced either isotropic or anisotropic. C3, C5 & C8 magnets are anisotropic. If you need the strongest magnetic materials, we suggest sintered NdFeB magnets like N52.

Specification & Magnetic Properties

Type: Permanent Magnet

Material: Sintered Ferrite

Grade: Y30, Y30BH, Y33 etc(Download Magnetic Property Sheet of Sintered Ferrite Magnets)

Shape & Size & Tolerance: According to clients’ requirement, can custom special & complex shapes

Application: industrial, motors, speaker, air conditioning systems, crafts, daily life, cow, etc.

Sintered Ferrite magnets are produced by adopting the method of powder metallurgy. They are low in remanence, small in magnetic permeability, bigger in Coercive force and strong in resistance to demagnetization, which are especially suitable used as the magnetic circuit structure of the dynamic working conditions. Ferrite material is hard and brittle, can be cut by silicon carbide tools. Isotropic ferrite permanent magnets are weak in magnetism but can be magnetized in different orientation. Anisotropic sintered ferrite magnets have strong magnetic performance, but only magnetized along the designated orientation.

The differences between NdFeB magnets and Ferrite magnets mainly include the following points:

1. In the appearance, Ferrite magnets are loose, with no metal luster, and generally supplied without plating. Ferrite magnets are usually in black color and are oxides, very stable, and not easy to rust. NdFeB magnets are alloys which are easy to oxidize and usually supplied with coating or they can be rusted easily. The surface of NdFeB is silvery white, with metallic luster or other colors.

2. The magnetic energy difference between NdFeB and Ferrite is huge. Magnetic energy product of NdFeB magnets can reach 53MGOe, while that of ferrite magnets is 6MGOe.

3. In terms of price, ferrite magnets are much cheaper than Nd-Fe-B magnets. Ferrite is mainly ferric oxide, while neodymium iron boron is mainly made of rare earth and iron.

4. Comparing with neodymium magnets, which easily demagnetize in high temperature, ferrite magnets have excellent temperature –resistance, of which magnetic strength are not readily weaken.

5. Ferrite magnets are easy to be magnetized with multi poles, but neodymium magnets are more difficult to do multi-pole magnetization direction.

Remark:

With high permeability, cheap price and high temperature resistance, ferrite magnets are applicable to working environment of low frequency. They are often used in loudspeakers and voice box.

Due to small size, light weight and strong magnetic strength, neodymium magnets have variety of applications and good mechanical characteristics. They are cost-effective and widely used in modern industry and electronic technology.

A New Design of Ferrite Magnetic Assembly 20181205

Y30 Ferrite Ring Magnets 20180428

Ferrite Permanent Magnets for Fan BLDC Motor 20170512

Shape & Size & Tolerance: According to clients’ requirement, Application: industrial, motors, speaker, air conditioning systems, crafts, daily life, cow, etc.

Type: Permanent MagnetMaterial: Sintered Ferrite()Shape & Size & Tolerance: According to clients’ requirement, Application: industrial, motors, speaker, air conditioning systems, crafts, daily life, cow, etc.

|